I-newellisiqandisi commercialiyidivayisi yesiqandisi eklanyelwe ngokukhethekile izindawo zentengiso, esetshenziswa kakhulu ezimeni ezehlukene zezentengiso njengezindawo zokudlela, izitolo ezinkulu, amahhotela, nokuningi. Ngesisekelo sokuhlangabezana nezidingo zesitoreji sezentengiselwano, umphumela wayo othule omangalisayo udonse ukunaka okukhulu. Lokhu akuhlinzeki nje kuphela isimo esinokuthula nesinethezekile endaweni yezohwebo kodwa futhi kunciphisa ukuphazamiseka nokungakhululeki okungase kubangelwe umsindo. Uma siqhathaniswa neziqandisi ezijwayelekile, isiqandisi se-nenwell sinemiklamo eyingqayizivele kanye nezinzuzo esicini sokuthula, okusenza sigqame emakethe.

I. Imininingwane Nokubaluleka Komklamo Othule Wefriji Yomkhiqizo we-nenwell

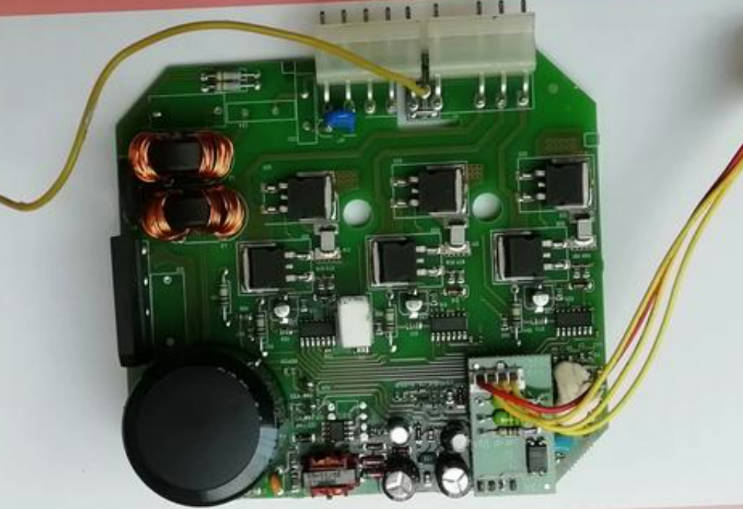

(I) Idizayini Ye-Compressor Ethuthukisiwe

- Ukukhethwa kwama-Compressor Asezingeni Eliphezulu

- Isiqandisi se-nenwell sokuhweba sikhetha ama-compressor ekhwalithi ephezulu. Lawa ma-compressor asezingeni elihamba phambili kubuchwepheshe namasu okukhiqiza. Isibonelo, basebenzisa izakhiwo ze-piston ezithuthukisiwe kanye nezinqubo zokukhiqiza ezinembayo, okwenza i-compressor isebenze kahle kakhulu futhi yehlise ukungqubuzana nokudlidliza phakathi kwezingxenye zangaphakathi. Lesi yisisekelo sokufeza umphumela onokuthula ngoba i-compressor iyisici esiyinhloko sesiqandisi, futhi isimo sayo sokugijima sithinta ngokuqondile izinga lomsindo wefriji yonke.

- Okubalulekile: Ama-compressor ekhwalithi ephezulu angaqinisekisa ukuthi isiqandisi sigcina ukusebenza kwesiqandisi okuzinzile ngesikhathi sokusebenza isikhathi eside futhi ngesikhathi esifanayo sinciphisa ukukhiqizwa komsindo. Ezindaweni zokuhweba, ukusebenza okuqhubekayo nokuzinzile kwesiqandisi kubalulekile. Uma i-compressor ivame ukuba nokwehluleka noma umsindo owedlulele, ngeke nje ithinte ikhwalithi yezinto ezigciniwe kodwa futhi iphazamise ukuqhubeka okuvamile kwemisebenzi yezohwebo.

- Ukusetshenziswa kobuchwepheshe bokudlidliza nomsindo wokunciphisa

- Ekufakweni kwe-compressor, i-nenwell isebenzisa amadivaysi achwephesha okudambisa amanzi. Isibonelo, kusetshenziswa amaphedi okudambisa irabha akhethekile, angamunca ngempumelelo amandla okudlidliza akhiqizwa lapho i-compressor isebenza. Lawa maphedi okudambisa ane-elasticity enhle nezici zokudambisa futhi anganciphisa ubukhulu bokudlidliza kwe-compressor edluliselwe ekhabetheni lesiqandisi.

- Ngasikhathi sinye, iphinde isebenzise inhlanganisela yezinyathelo eziningi zokuthambisa ezifana nezinhlelo zokudambisa intwasahlobo ukuze kuthuthukiswe umphumela wokudambisa. Engxenyeni yokuxhumeka kwepayipi ye-compressor, izinto zokuxhuma eziguquguqukayo nazo zisetshenziselwa ukunciphisa ukudluliswa komsindo obangelwa ukudlidliza kwepayipi.

- Okubalulekile: Ukusetshenziswa kobuchwepheshe bokudlidliza kanye nokunciphisa umsindo kunganciphisa kakhulu umsindo okhiqizwa lapho i-compressor isebenza, idale indawo ethule kancane yendawo yezohwebo. Ezindaweni zokudlela nakwezinye izindawo, indawo ethulile ingathuthukisa umuzwa wokudlela wamakhasimende; emahhotela nakwezinye izindawo, ingase futhi inikeze izivakashi indawo yokuhlala enethezeke kakhudlwana, igweme umthelela wokuphumula kwezivakashi ngenxa yomsindo wesiqandisi.

(II) Idizayini ye-Air Duct Enengqondo

- I-Smooth Air Duct Isakhiwo

- Idizayini yepayipi lomoya yesiqandisi se-nenwell sezentengiselwano yenziwe ngokucophelela ukuze kuqinisekiswe ukuthi ukugeleza komoya ngaphakathi kwesiqandisi kubushelelezi. Umumo nosayizi wepayipi lomoya kubalwe ngokunembile ukuze kugwenywe ukuphenduka okubukhali nokuvinjwa kokugeleza komoya. Isibonelo, i-arc-shaped air duct design yamukelwa ukuze kuncishiswe ukumelana komoya epayipini lomoya, ukuze umoya udlule kahle endaweni ngayinye yesiqandisi.

- Ngesikhathi esifanayo, izikhundla zezindawo zokukhipha umoya kanye nezindawo zokubuyisela umoya zihlelwe ngokunengqondo ukuze umoya obandayo usabalalise ngokulinganayo kuwo wonke amagumbi esiqandisi, kuthuthukiswe ukusebenza kahle kwesiqandisi nokunciphisa umsindo ovezwa ukugeleza komoya okuphazamisekile.

- Okubalulekile: Ukwakheka kwepayipi lomoya elibushelelezi kungathuthukisa umphumela wesiqandisi wesiqandisi futhi kunciphise umsindo obangelwa ukugeleza komoya okungasheleli. Ekusetshenzisweni kwezentengiselwano, isiqandisi esisebenzayo singaqinisekisa ikhwalithi yezinto ezigciniwe, futhi umsindo ophansi usiza ukudala isimo esihle sokuhweba futhi uthuthukise ukwaneliseka kwamakhasimende noma izivakashi.

- Ukusetshenziswa Kwezinto Zokunciphisa Umsindo

- Ngaphakathi komgudu womoya, i-nenwell isebenzisa izinto ezimunca umsindo. Lezi zinto ezimunca umsindo ngokuvamile zinesakhiwo esinezimbotshana futhi zingamunca ngempumelelo amandla omsindo akhiqizwa lapho umoya udlula. Isibonelo, ukotini omunca umsindo unamathiselwe odongeni lwangaphakathi lwepayipi lomoya, futhi lokotini omunca umsindo ungaguqula ingxenye yomsindo ube amandla okushisa futhi uwuqede, ngaleyo ndlela wehlise ukudluliswa komsindo.

- Okubalulekile: Ukusetshenziswa kwezinto zokunciphisa umsindo kuthuthukisa futhi umphumela othule wepayipi lomoya, okwenza isiqandisi sisebenze ngokuthula. Kwezinye izindawo zezentengiselwano ezizwelayo enomsindo, njengezitolo ezisezakhiweni zamahhovisi, lo mklamo onemininingwane ubaluleke ngokukhethekile futhi ungagwema umthelela womsindo wesiqandisi endaweni ezungezile yamahhovisi.

(II) Umklamo Onembayo Wesakhiwo SeKhabhinethi

- Amapuleti eKhabhinethi Aminyene

- Ikhabethe lesiqandisi se-nenwell lenza amapuleti awugqinsi. Ngokuvamile, amapuleti aseceleni, amapuleti aphezulu, namapuleti aphansi ekhabhinethi wonke anogqinsi oluthile. Isibonelo, ubukhulu bamapuleti aseceleni bungase bufinyelele kumamilimitha ambalwa noma ngisho nakakhulu, okungagcini nje ukuthuthukisa amandla esakhiwo sekhabhinethi kodwa futhi kuvimbela ngokuphumelelayo ukudluliswa kwangaphandle komsindo ngaphakathi kwesiqandisi.

- Lawa mapuleti ngokuvamile enziwa ngenhlanganisela yezinto ezisezingeni eliphezulu zokugqumisa kanye nezinto zensimbi, ezinokusebenza okuhle kokufakwa komsindo. Izinto zokufakelwa zinganciphisa ukushintshaniswa kokushisa phakathi kwangaphakathi nangaphandle kwesiqandisi futhi zidlale indima ethile ekumunceni umsindo, kuyilapho izinto zensimbi zinikeza ukusekelwa kwesakhiwo.

- Okubalulekile: Amapuleti ekhabhinethi aminyene anganikeza isithiyo esihle sokufaka umsindo esiqandisini, sinciphise umbono wendawo yangaphandle kumsindo wokusebenza ngaphakathi kwesiqandisi. Esimeni sezentengiselwano, ikakhulukazi ezindaweni eziminyene njengezitolo ezinkulu, kunganciphisa umthelela womsindo wesiqandisi kumakhasimende futhi kuthuthukise ulwazi lokuthenga.

- Idizayini Yokufaka uphawu Enhle

- Iziqephu zokuvala ezisezingeni eliphezulu zisetshenziswa phakathi komnyango kanye nekhabhinethi yesiqandisi ukuze kuqinisekiswe ukubekwa uphawu okuhle. Le micu yokuvala inezici zokuthamba nokuba nokunwebeka okuhle futhi ingangena eduze emnyango nasekhabetheni, ivimbele ukuvuza komoya futhi inciphise nendlela yokudlulisa umsindo.

- Ngaphezu kwalokho, ekwakhiweni komnyango, ezinye izakhiwo ezikhethekile nazo zamukelwa, ezifana nomklamo womnyango we-double-layer noma umnyango onomshini wokudonsa kazibuthe, othuthukisa ngokwengeziwe ukusebenza kokuvala umnyango. Uma umnyango uvaliwe, ungavimbela ngokuphumelelayo umsindo ongaphakathi kwesiqandisi ukuthi ungasakazeki ngaphandle.

- Okubalulekile: Umklamo omuhle wokuvala ngeke uthuthukise ukusebenza kahle kwesiqandisi kuphela futhi unciphise ukusetshenziswa kwamandla kodwa futhi unciphise kakhulu izinga lomsindo. Ezindaweni ezidinga indawo enokuthula njengamagumbi ehhotela, ukusebenza kahle kokuvala umnyango wesiqandisi kungaqinisekisa ukuthi izivakashi ngeke ziphazanyiswe umsindo wesiqandisi phakathi nokuphumula.

(III) Ubuchwepheshe Bokulawula Isistimu Yesiqandisi Ethuthukisiwe

- Intelligent Frequency Conversion Technology

- Isiqandisi se-nenwell sezentengiselwano samukela ubuchwepheshe bokuguqula imvamisa ehlakaniphile, engalungisa ngokuzenzakalelayo isivinini sokujikeleza se-compressor ngokuya ngokushintsha kwezinga lokushisa kanye nesidingo sangempela ngaphakathi kwesiqandisi. Lapho izinga lokushisa ngaphakathi kwesiqandisi liseduze nezinga lokushisa elibekiwe, i-compressor ingagijima ngesivinini esiphansi, inciphise ukusetshenziswa kwamandla kanye nokwenza umsindo.

- Isibonelo, ebusuku noma lapho kunezinto ezimbalwa esiqandisini, isistimu yokuguqula imvamisa ehlakaniphile inganciphisa ngokuzenzakalelayo imvamisa yokusebenza ye-compressor, igcine isiqandisi esimweni esisezingeni eliphansi esizinzile futhi sinciphise izinga lomsindo. Futhi emini noma lapho kunezinto eziningi esiqandisini futhi isiqandisi esisheshayo siyadingeka, i-compressor ingandisa ngokuzenzakalelayo isivinini sokujikeleza ukuze kuqinisekiswe umphumela wesiqandisi.

- Okubalulekile: Ukusetshenziswa kobuchwepheshe bokuguqula imvamisa ehlakaniphile kufeza imiphumela ekabili yokonga amandla kanye nokunciphisa umsindo. Kubasebenzisi bezentengiselwano, ukonga amandla kunganciphisa izindleko zokusebenza, futhi ukunciphisa umsindo kuthuthukisa ikhwalithi yemvelo. Kwezinye izindawo zokuthengisa ezidinga ukusebenza amahora angama-24 ngosuku, njengezitolo ezilula, inzuzo ethule yesiqandisi esihlakaniphile sokuguqula imvamisa isobala kakhulu.

- Izinzwa Zezinga Lokushisa Eziqondile kanye Nezinhlelo Zokulawula

- Isiqandisi sifakwe izinzwa zokushisa ezinembayo ezikwazi ukuqapha ngokunembile izinga lokushisa endaweni ngayinye ngaphakathi kwesiqandisi ngesikhathi sangempela. Lezi zinzwa zidlulisela idatha yokushisa ohlelweni lokulawula, futhi uhlelo lokulawula lulawula ngokunembile ukusebenza kwesistimu yesiqandisi ngokusho kwemingcele yokushisa esethiwe kanye nesimo sangempela sokushisa.

- Ngokulawula okunembile, isistimu yesiqandisi ingasebenza ngokuzinza, igwema ukuqala nokuma kwe-compressor okubangelwa ukushintshashintsha kwezinga lokushisa okudlulele, ngaleyo ndlela kuncishiswe ukudalwa komsindo. Isibonelo, isistimu yokulawula ingakwazi ukulawula ukuguquguquka kwezinga lokushisa phakathi kwebanga elincane kakhulu, okwenza i-compressor ihambe kahle futhi inciphise umsindo womthelela okhiqizwa ngesikhathi sokuqalisa nokuvala.

- Okubalulekile: Izinzwa zokushisa ezinembile kanye nezinhlelo zokulawula ziqinisekisa ukunemba kwesiqandisi kanye nokuzinza kwesiqandisi futhi futhi zinciphisa ngempumelelo umsindo. Lapho ugcina izinto ezinezidingo zokushisa okuphezulu, njengemithi nokudla okuphezulu, lokhu kulawulwa okunembile kwezinga lokushisa nokusebenza okuthulile kubaluleke kakhulu futhi kungaqinisekisa ikhwalithi nokuphepha kwezinto.

IV. Isiphetho

Isizathu sokuthi kungani uhlobo lwesiqandisi se-nenwell sezentengiselwano lungafinyelela ukusebenza okuhle kokuthula kungenxa yokuklama okucophelela kanye nokusetshenziswa kobuchwepheshe ezicini eziningi. Kusukela ekwakhiweni kwe-compressor okulungiselelwe, okuhlanganisa ukukhethwa kwezigaxa zekhwalithi ephezulu kanye nokusetshenziswa kobuchwepheshe bokudlidliza obuthuthukisiwe nomsindo wokunciphisa umsindo, ukuya ekwakhiweni kwemigudu yomoya enengqondo ukuze kuqinisekiswe ukugeleza komoya okushelelayo nokunciphisa ukudluliswa komsindo; bese kuba umklamo onembile wesakhiwo sekhabhinethi, usebenzisa amapuleti awugqinsi nokuvala kahle ukuvimba umsindo; kanye nobuchwepheshe bokulawula isistimu yesiqandisi ethuthukisiwe, njengobuchwepheshe bokuguqula imvamisa ehlakaniphile nokulawula izinga lokushisa okunembile.

Le mininingwane yedizayini iyasebenzisana futhi isebenza ndawonye, okwenza isiqandisi se-nenwell sinikeze indawo ethule nenethezekile yokusebenzisa kubasebenzisi ngenkathi ihlangabezana nezidingo zesiqandisi sezentengiso. Ezindaweni zentengiso, ukukhetha isiqandisi se-nenwell ngeke kuqinisekise ikhwalithi yezinto ezigciniwe kuphela kodwa futhi kuthuthukise ikhwalithi iyonke yendawo yokusebenza futhi kunciphise ukuphazamiseka komsindo kumakhasimende, abasebenzi, noma izivakashi. Kungakhathaliseki ukuthi indawo yokudlela, isitolo esikhulu, ihhotela, noma ezinye izindawo zentengiso, inzuzo ethule yesiqandisi se-nenwell isenza kube ukukhetha okuthembekile.

Ngokuzayo, ngenqubekelaphambili eqhubekayo yobuchwepheshe kanye nokwenza ngcono okuqhubekayo kwezidingo zabasebenzisi, kukholakala ukuthi uhlobo lwe-nenwell luzoqhubeka nokusungula nokuthuthukisa isici somklamo othule, iletha imikhiqizo emihle kakhulu endaweni yeziqandisi zentengiso.

Isikhathi sokuthumela: Oct-25-2024 Ukubukwa: